These 2MW series wind turbines are double-fed, variable pitch windmills. The wind generators can be produced with rotor diameters of 87 / 93 / 99 / 105 / 111/116 meters. This allows for wind power generation in wind classes from I to IV.

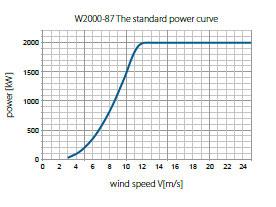

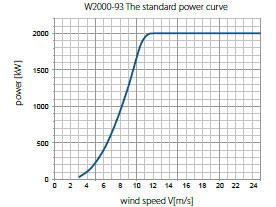

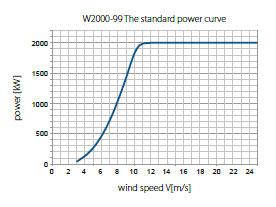

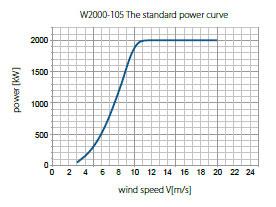

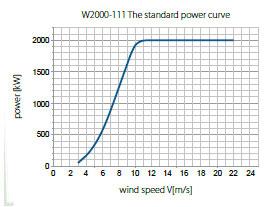

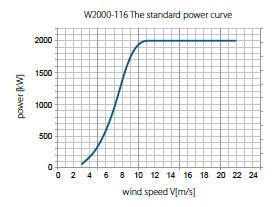

W2000-87/93/99/105/111/116 power curve

| Operating data |

| Rated power[kw] |

2000 |

| Cut-in wind speed[m/s] |

3 |

| Cut-out wind speed[m/s] |

25/25/25/20/22/25 |

| Wind class |

IEC I B/IECII B/IECIII A/IECIII B/IEC S/IECS |

| Maximum wind speed(3s)[m/s] |

70/59.5/52.5/52.5/52.5/52.5 |

| Operating temperature(℃) |

[-20,+40](Normal temperature) [-30,+40](Low temperature) |

| Survival temperature(℃) |

[-30,+50](Normal temperature) [-40,+50](Low temperature) |

| Rotor speed range[rpm] |

8.33-16.5/8.33-16.5/8.33-16.5/8.33-16/7.87-16/7.87-16 |

| Rated speed range[rpm] |

15.35/15.35/15.35/15/14.5/14.5 |

| Rated wind speed[m/s] |

11.4/10.8/10.4/10/9.5/9.2 |

| Life cycle[year] |

20 |

| Surface color |

Light gray RAL7035 |

| Rotor weight[t] |

43.2/42.5/45.6/48.6/51.3/51.8 |

| Hub weight[t] |

17.5 |

| Nacelle weight[t] |

82 |

| Rotor |

| Rotor diameter[m] |

87/93/99/105/111/116 |

| Swept area[㎡] |

5942/6789/7693/8659/9677/10565. |

| Blade Amount |

3 |

| Rotor tilt[°] |

5 |

| Rotor cone angle[°] |

3.5/3.5/3.5/3.5/5/5 |

| Blade |

| Type |

| Blade length[m] |

42.38/45.38/48.38/51.38/54.38/56.88 |

| Aerodynamic configuration |

Aerodyn AE+NACA |

| Blade material |

GFRP |

| Pitch System |

| Type |

Electric pith system |

| Pitch speed[°/s] |

5 |

| Pitch bearing |

Four-point contact ball |

| Drive chain |

| connection |

Rotor hub-rotor shaft: flange; Rotor shaft-gearbox: shrink disk; Gearbox generator: Double flexible coupling |

| Gearbox type |

1-Stage parallel axis |

| gearbox gear ratio |

118/118/118/118/125/125 |

| gearbox lubricating system |

Force+ splash lubricating |

| gearbox oil[L] |

~400 |

| gearbox oil filter |

On line(can match offline precision filtration) |

| Gearbox cooling |

Oil-water-wind refrigeration |

| Generator |

| Type |

Doubly fed induction generator |

| Rated power[kw] |

2100 |

| Rated speed[rpm] |

983-1983 |

| Rated voltage[v] |

690 |

| Grid frequency[Hz] |

50 |

| insulation |

F、H |

| protection |

IP54 |

| Type of cooling |

Water cooling |

| Converter |

| Type |

| Apparent power[KVA] |

2100 |

| Rated voltage[v] |

690 |

| Grid frequency[Hz] |

50 |

| Type of cooling |

Water cooling |

| Yaw system |

| Type |

Electric yawing system |

| Yaw bearing |

Four-point contact ball |

| Yaw motor |

4 Pieces |

| Yaw rate[°/s] |

0.68 |

| Braking system |

| Type |

Main braking: blade aerodynamic brakes Mechanical braking: High speed shaft mechanical brakes |

| Main braking |

Blade Paddle brakes |

| Mechanical braking |

High-speed spindle hydraulic disc caliper brake |

| Loading components |

| Hub |

Nodular cast iron |

| Rotor bearing |

Double row spherical roller bearing |

| Rotor |

Alloy steel |

| Front frame |

Nodular cast iron |

| Back frame |

Structural steel parts |

| Nacelle cover(Dome) |

GFRP |

| Control system |

| Control unit |

PLC |

| Process control system |

Distributed control |

| Bus control type power link |

Power link |

| Remote control |

SCADA |

| Tower |

| Type |

cylindrical |

| Hub height[m] |

80m or According to the site condition |

| Antiseptic |

Anticorrosion painting |

| Anticorrosion painting |

Following the ISO12944 standards, according to the wind field environment. |

| Barrel |

Structural steel |

| Flange |

Circular forging steel |